Introduction

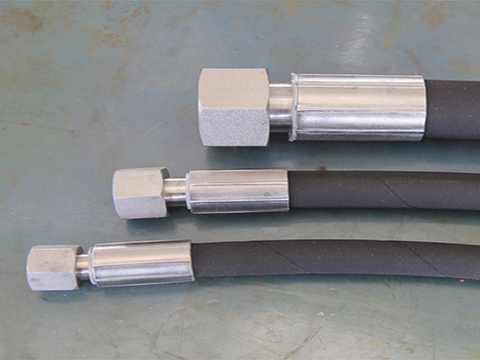

Rubber wear-resistant tubing plays a vital role in various industries, providing a reliable and durable solution for fluid transfer in harsh environments. These tubing systems are designed to withstand abrasion, impact, and other challenging conditions, ensuring the safe and efficient transportation of liquids and gases. This article will explore the benefits of rubber wear-resistant tubing and highlight its significance in diverse applications.

- Resistance to Abrasion

One of the key advantages of rubber wear-resistant tubing is its exceptional resistance to abrasion. In industries such as mining, construction, and material handling, where fluids containing solid particles or abrasive materials are present, this tubing is vital for transferring liquids without suffering from premature wear. The wear-resistant properties of rubber tubing help extend its lifespan, reduce maintenance costs, and minimize downtime.

- Impact Resistance

Rubber wear-resistant tubing is also highly resistant to impact. In industries such as agriculture, where tubing systems are exposed to rough handling or potential impact from machinery or equipment, this tubing provides excellent protection. The ability to withstand impact ensures the integrity of the tubing system, preventing leaks and maintaining efficient fluid transfer.

- Flexibility and Maneuverability

Rubber wear-resistant tubing offers excellent flexibility and maneuverability, making it easier to install and route in complex systems. Its flexibility allows it to bend and adapt to various angles and corners, reducing the need for additional fittings and connectors. This flexibility also enhances ease of maintenance, as it simplifies the replacement or repair of damaged sections.

- Chemical Resistance

Another significant benefit of rubber wear-resistant tubing is its resistance to a wide range of chemicals. Industries such as chemical processing, pharmaceuticals, and food and beverage rely on this tubing to transport corrosive or aggressive fluids safely. The chemical resistance of rubber tubing ensures that it remains intact and unaffected by the substances it encounters, minimizing the risk of leaks or contamination.

- Temperature Resistance

Rubber wear-resistant tubing is designed to withstand extreme temperature variations. Whether in high-temperature processes or cryogenic environments, this tubing maintains its integrity and performance. The ability to withstand a wide temperature range without degradation makes rubber tubing suitable for diverse applications, from industrial to medical.

Conclusion

Rubber wear-resistant tubing offers numerous benefits in harsh environments. Its high resistance to abrasion and impact ensures longevity and performance, reducing maintenance costs and downtime. The flexibility and maneuverability of rubber tubing facilitate easy installation and maintenance, while its chemical and temperature resistance make it suitable for a wide range of industries. Understanding the benefits of rubber wear-resistant tubing is crucial for selecting the appropriate tubing system that can withstand the demanding conditions of various applications. By choosing the right tubing, industries can ensure efficient fluid transfer, prolong the lifespan of their systems, and enhance overall productivity.