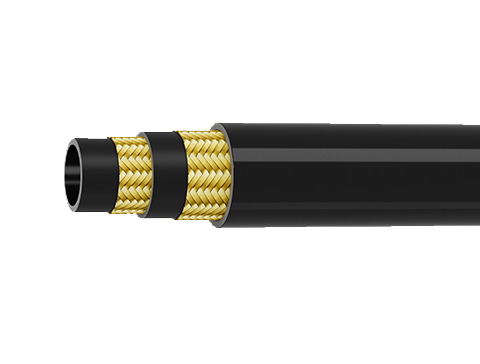

Artery Wire Braid Hydraulic Rubber Hose

|

SIZE |

SIZE |

I.D.(mm) |

Max.W.P. |

Min.B.P. |

Min.B.R. |

|

|

Min |

Max |

(MPa) |

(MPa) |

(mm) |

||

|

-4 |

1/4—1 |

5.8 |

6.5 |

25 |

100 |

80 |

|

-5 |

5/16—1 |

7.7 |

8.5 |

25 |

100 |

92 |

|

-6 |

3/8—1 |

9.8 |

10.5 |

21 |

84 |

104 |

|

-8 |

1/2—1 |

12.8 |

13.5 |

18 |

72 |

144 |

|

-10 |

5/8—1 |

15.8 |

16.6 |

14 |

56 |

160 |

|

-12 |

3/4—1 |

18.8 |

19.8 |

14 |

56 |

192 |

|

-16 |

1—1 |

24.8 |

25.8 |

9 |

36 |

240 |

| -20 |

1 1/4—1 |

31.4 |

33 |

6.3 |

25 |

400 |

-24 |

1 1/2—1 |

37.7 |

39.3 |

5 |

20 |

480 |

|

-32 |

2—1 |

50.4 |

52 |

4 |

16 |

560 |

|

-4 |

1/4—2 |

5.8 |

6.5 |

42 |

168 |

80 |

|

-5 |

5/16—2 |

7.7 |

8.5 |

35 |

168 |

92 |

|

-6 |

3/8—2 |

9.8 |

10.5 |

35 |

140 |

104 |

|

-8 |

1/2—2 |

12.8 |

13.5 |

28 |

112 |

144 |

|

-10 |

5/8—2 |

15.8 |

16.6 |

28 |

112 |

160 |

|

-12 |

3/4—2 |

18.8 |

19.8 |

25 |

100 |

192 |

|

-16 |

1—2 |

24.8 |

25.8 |

21 |

84 |

240 |

|

-20 |

1 1/4—2 |

31.4 |

33 |

14 |

56 |

400 |

|

-24 |

1 1/2—2 |

37.7 |

39.3 |

9 |

36 |

480 |

|

-32 |

2—2 |

50.4 |

52 |

8 |

32 |

610 |