Hydraulic hoses play a crucial role in various industries where the transfer of fluid power is essential. One important aspect to consider when working with hydraulic hoses is the relationship between their length and the pressure they can handle. Understanding this connection is vital for ensuring the efficient and safe operation of hydraulic systems.

When it comes to hydraulic hoses, their length directly influences the pressure they can handle. As the length of the hose increases, the pressure drops due to various factors such as friction and resistance within the hose itself. This phenomenon is known as pressure drop or pressure loss. It is important to consider this factor when designing hydraulic systems to ensure that the pressure requirements are met throughout the system.

To illustrate this relationship, let’s consider an example. Imagine a hydraulic system that requires a specific pressure of 1000 psi at the end of a 10-meter long hose. However, due to the pressure drop that occurs along the length of the hose, the initial pressure at the source needs to be higher. Calculations based on the hose’s diameter, material, and specific flow rates can help determine the required initial pressure to compensate for the pressure drop and attain the desired pressure at the end of the hose.

It is important to note that the relationship between hose length and pressure is not linear. As the length of the hose increases, the pressure drop becomes more significant. Therefore, it is crucial to keep the hose length as short as possible while still meeting the operational requirements. This can help minimize pressure losses and improve the overall efficiency of the hydraulic system.<br/>

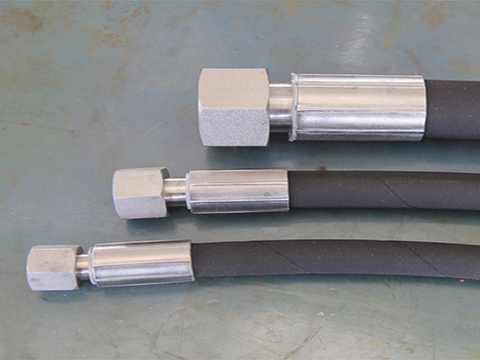

When working with longer hose lengths, it is also essential to consider the type and quality of the hose being used. High-quality hoses with low friction coefficients and excellent resistance to pressure can help reduce the impact of length on pressure. Additionally, the proper selection of hose fittings and connectors can contribute to minimizing pressure drop along the length of the hose.

In conclusion, the length of hydraulic hoses has a direct impact on the pressure they can handle. Understanding and considering the relationship between hose length and pressure is crucial for designing and operating efficient hydraulic systems. By minimizing pressure losses through appropriate hose selection, length optimization, and careful system design, one can ensure the optimal performance and longevity of hydraulic systems.